As the exhibit and event world attended ExhibitorLive in Louisville, Kentucky this week, we thought it would be a great opportunity to catch up with beMatrix’s Director of Marketing, Kent Agramonte and CDI World USA’s president, Durl Jensen, to talk about sustainability, the beauty of modular design, and what the future holds for booth design.

Kent, thanks for taking the time to meet us; we know that the trade show season is particularly busy! It is obviously a huge compliment to CDI World USA that you have chosen to partner with them for the ExhibitorLive tradeshow. So, why did you choose CDI world?

We chose to work with CDI World on the ExhibitorLive Tradeshow because colleagues of mine have worked with them before. I was confident that they could do what I needed them to do, and that they would understand the brief.

Sustainability used to be a choice or even a luxury; now it is a must-have.

Do you think that working with CDI World USA has been made easier because they are so familiar with your modular system?

Absolutely. Because they know our system so well, there was no need for any handholding from me. They knew exactly what needed to be done. With this particular booth, there are new elements that we wanted to showcase, and working with the CDI team meant that this was easier than anticipated; because they knew the system so well that introducing new concepts was straightforward.

How have you seen the market for modular systems change in recent years?

The biggest change in the booth building and events industry is the ongoing drive for sustainability. Sustainability has always been important to us as an organization, but increasingly it is important to our clients, too. Our clients – people like CDI World – are under increasing pressure from their clients to help them to meet sustainability targets. If you can show that your booth is sustainable it is a huge selling point, and it is becoming even more valuable as sustainability becomes more prominent.

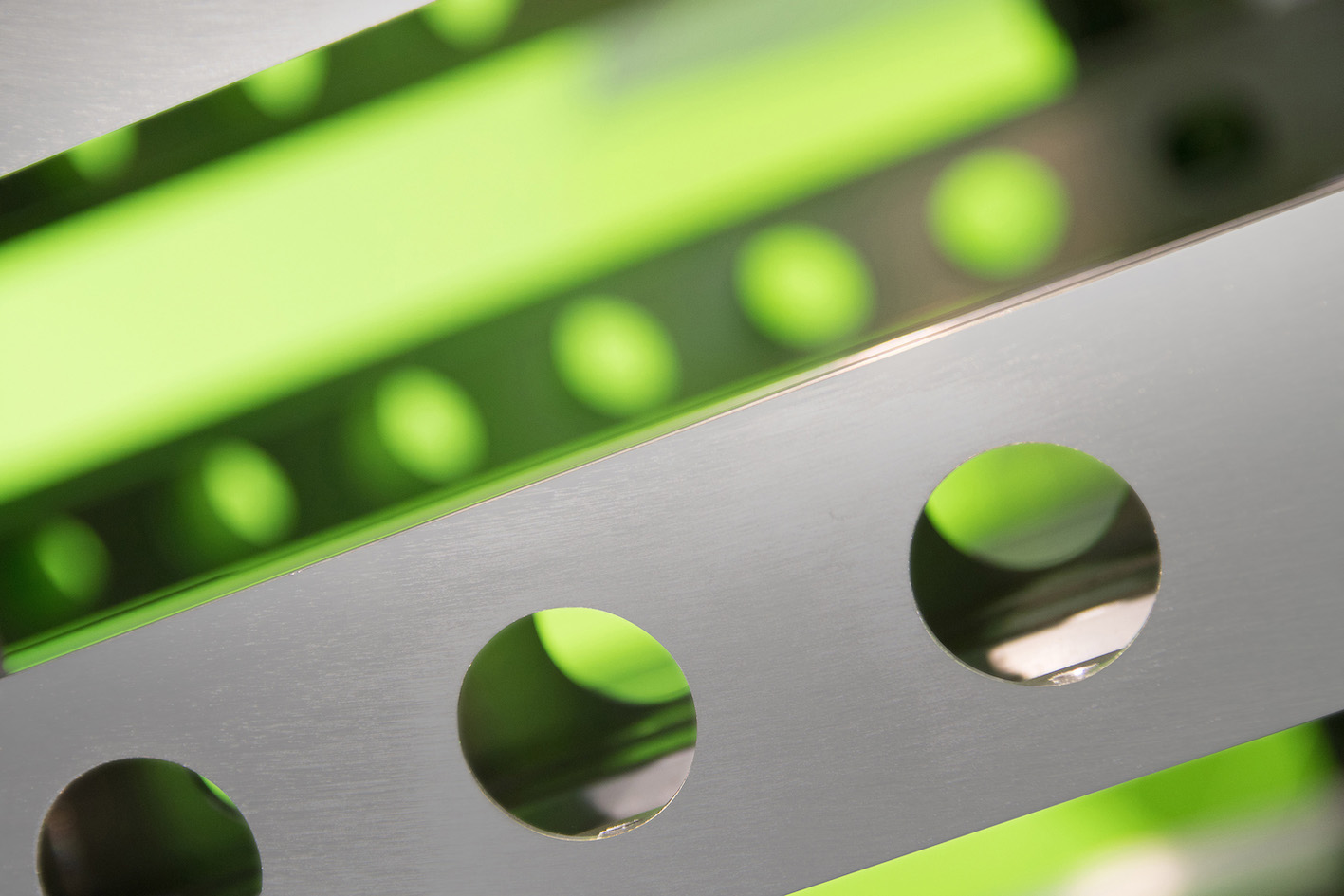

At beMatrix, sustainability is at the heart of everything we do. Our frames are made from aluminum which is lightweight and recyclable.

In recent years, we have seen the market change completely. The decision makers are younger. They understand the need for sustainability, and they have targets to reach that their investors demand. Sustainability used to be a choice or even a luxury; now it is a must-have. Sustainability is even accounted for in event attendance. Clients look at the number of reps attending, how they travelled there, and their overall carbon footprint. Sustainability is becoming the norm and even organizations who have resisted it in the past will have to embrace it in the near future.

That may see you going from a unique industry leader to the norm; does that mean you will have greater industry competition? Are you worried?

In a word, no! There is nothing wrong with everyone becoming more sustainable, whatever their motivations. It is just important that people don’t greenwash. While we encourage sustainable activities, we will always be unique because we hold those values of sustainability close. We are committed to it; our sustainability policy is on our website for everyone to see. It’s not about competition, it’s about minimizing our impact, and that of our clients.

You are clearly passionate about minimizing your and your clients’ carbon footprints. With your considerable experience in the industry, what do you think will be the big trends of 2023 and beyond?

The overarching theme is, of course, sustainability but for me there are two things that will be big. The first is infills. Right now, across the world, non-sustainable products are used to cover booths, and in the past, nobody has even considered recycling or repurposing. Now, fabrics are being shredded, repurposed, and recycled. And it’s not just fabric infills. We are also seeing a rise in the use of sustainable hard infills. The big thing is, people are accepting that it’s not just the booth skeleton that can be used sustainably; infills can, too.

The other big thing is the ability to use intelligent software so that people can design their booth and work out their carbon footprint straight away. At the exhibition we showcased MybeMatrix, a suite of beMatrix software solutions designed to streamline the design and management of a exhibit or event project. One capability of MybeMatrix is our carbon footprint calculator, which enables clients to calculate the carbon footprint of their design and finish, making sustainability a central consideration throughout the process.

When your booth launched earlier this week, what do you think exhibit visitors got most excited about?

We are excited about the whole thing! But there are two things in particular that I was excited to showcase. The first is our new toolless connector Fast Clamp. With the current connector, it is necessary for the cap to be twisted off and reconnected. This takes a small amount of time, but a small amount of time multiplied hundreds of times can add up to a lot. It is also not uncommon for the caps to be lost. When this happens, aside from the inconvenience, the toolless connector cap needs to be replaced. Our new Fast Clamp dispenses with the screw cap. Just push, twist, let go, and it locks into place. No more lost caps means less waste and better inventory management, but the real saving is in labor time.

The second element is the new beConstruct profile. beConstruct consists of long pieces of aluminum extrusion which allows exhibit and event builders to achieve a more open floor space, without the need for rigging. Another huge saver in terms of time and labor.

That sounds fantastic and we can’t wait to see footage of the booth and the new innovations. It is always fantastic to see two organizations that are so well aligned working together. Durl, as president of CDI World, what does this partnership mean to you?

This all started when our clients started asking questions and applying pressure for us to reduce weight. We knew that we would have to go out there and invest – and continue to invest- in something sustainable and high quality. Using beMatrix compared to wooden frames reduces drayage weights from 95lb to 19 lbs. That’s vital to us from a sustainability perspective but also with drayage more than doubling in cost per pound, it offers huge savings for our clients, too. The matter of labor makes another huge difference to the bottom line; we don’t need rigging with beMatrix and can just use ladders while getting the best results for our customers. The frames fit precisely with no gaps or issues with alignment, which makes fitting infills quicker and more effective. Using beMatrix allows us to accomplish great things with minimal environmental impact.

I am happy and appreciative of the partnership that CDI World USA have been able to establish with beMatrix and am delighted that we have been able to work together for this event.

To get in touch with one of our dedicated account managers today to discuss modular systems for your next exhibition.

Talk to us today to find out how we can support you with your exhibit or event, ensuring a memorable and impactful brand experience.

Contact Us